How to Find Your Equipment Model Number.

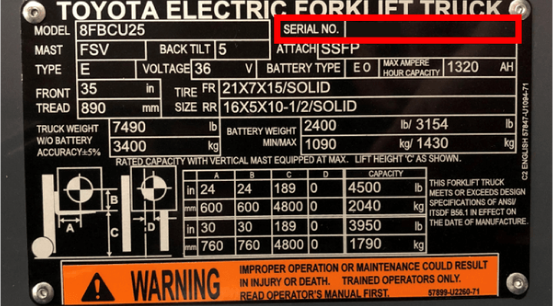

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

How to Find Your Equipment Serial Number

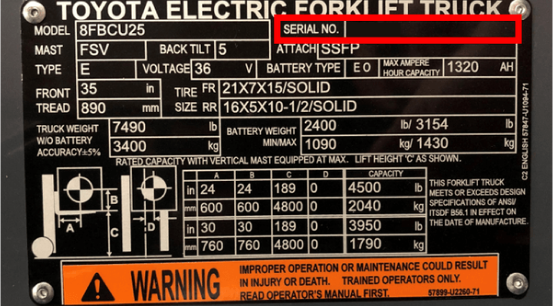

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

Need some help? For further assistance or more information, contact your local Toyota Dealer.

Please click below to sign in to your MyToyota account

Don't have an account?

Realizing ROI Through Toyota Lean Management

Toyota Lean Management or “TLM” focuses on investing in people, culture, and standard processes so that you can optimize your business by reducing waste. While the immediate goal is to reduce waste, one of the primary benefits from these activities is a positive return on investment.

TLM helps you focus on things that are within your control. While external factors like your market and the overall economy will always change, your internal processes can always be improved to reduce your costs and improve quality.

Here are just a few examples of the types of ROI improvements that you may realize by leveraging TLM.

- Reduced production time improves productivity, reduces labor costs, and gets product to market faster.

- Improving ergonomics by standardizing and organizing work stations can help reduce the likelihood of workplace injuries.

- Reducing transportation time when moving product can reduce labor costs as well as energy consumption.

- Improved morale due to a better work environment and culture can reduce turnover and consequently training time and onboarding costs.

- Using “Just-in-Time” production methods reduces overproduction and inventory storage costs.

- Leveraging “Jidoka” addresses problems when they are detected to help improve quality and reduce warranty claims.

While not all of these improvements are quantifiable or easily traced back to TLM, they all can have very significant, long-term impacts when it comes to your bottom line. Implementing TLM, however, isn’t as simple as flipping a switch. It takes time and dedication to the process as well as buy-in throughout the organization to truly leverage your lean potential.

If you’re interested in learning more about Toyota Lean Management and how to get started on your lean journey, be sure to reach out to your local, authorized Toyota forklift dealer. They can help improve your operations through lean site visits and facility tours, and they can share lean principles to help improve your ROI and efficiency.