Ruan and DC Logistics Customer Story

Jack for All Trades

Toyota’s pallet jacks put a positive charge into the delivery of car batteries

Automobile batteries can be difficult to handle. A full pallet of these lead blocks can weigh thousands of pounds. They also contain battery acid, so care must be taken not to drop them and to keep them upright at all times.

For these reasons, third-party companies such as Ruan Transportation Management Systems and DC Logistics specialize in distributing lead acid batteries. Headquartered in Des Moines, Iowa, Ruan is a family-owned asset-based 3PL. DC Logistics is a West Coast warehousing and distribution provider. The two companies share a battery-manufacturing client, with DC Logistics handling distribution and Ruan providing transportation to retail stores. For both companies, Toyota forklifts and Toyota electric pallet jacks perform the heavy lifting.

Power Move

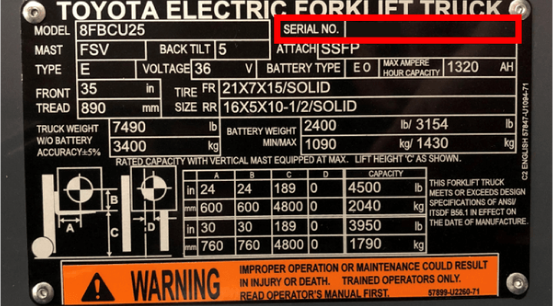

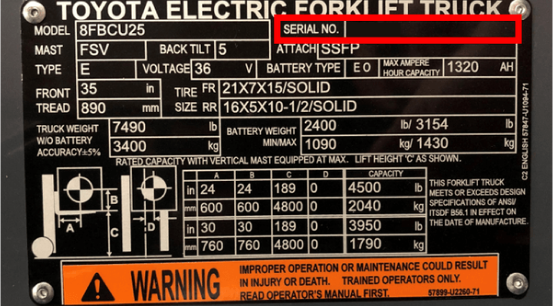

The manufacturer ships pallets of batteries to DC Logistics’ distribution facility in City of Industry, Calif. These are unloaded from trailers using Toyota sit-down counterbalanced forklifts. The pallets are then crossdocked onto local delivery trucks owned by Ruan. Ruan delivers the batteries to area retailers and wholesalers, including big-box automotive centers.

In metro markets, Ruan typically uses smaller delivery trucks that are able to maneuver on city streets, through parking lots, and to the back of retail buildings. Many of the stores lack loading docks, so the trucks take along Toyota electric-powered pallet jacks.

“The nature of our deliveries requires our drivers to utilize a lift-gate trailer along with the electric pallet jack to make deliveries into the retail and wholesale outlets,” explains Ryan Frederiksen, vice president of operations at Ruan Transportation.

An operator gathers a pallet of batteries and then uses the lift gate to lower the jack and the pallet to the ground. The tight turning radius of the pallet jack makes it very easy for the operator to maneuver the load. Contributing to this ease of movement is Toyota’s Click-to-Creep feature, which allows the operator to turn or move the pallet jack forward or back at the slow speed of 1 mile per hour with the handle fully upright.

“The maneuverability inside the trailer is something that we hear about from our drivers who are utilizing it every day,” says Frederiksen. “It also allows our drivers to maneuver the pallet on the lift gate that’s extended at the back of the trailer five or six feet off the ground. It has provided an incredible amount of safety to the operation of that device.”

Once the lift gate reaches ground level, the operator rolls the pallet jack and its load off the lift gate and into the retail location, sometimes directly onto the selling floor.

Returns for Recycling

Automotive batteries are among the most commonly recycled consumer products, so companies that distribute them also have a reverse supply chain process in place.

On most deliveries, the Ruan driver collects a pallet or two of used batteries from the retailer and loads them back onto the delivery truck. Ruan’s customized Toyota electric pallet jacks are specially equipped with electronic scales to accurately record the weight of the retrieved pallet loads. The used batteries are returned to the distribution center, where DC Logistics will funnel them into recycling channels.

DC Logistics works primarily with one of Toyota’s Southern California dealers, Southwest ToyotaLift, to keep its forklifts and pallet jacks in top working order. Ruan works directly with the Toyota factory for new orders and many local dealers across North America for service and repairs. Quality and service are what keep these two companies returning again and again to Toyota.

“Between all the facilities, we have approximately 40 Toyota forklifts and approximately 25 electric pallet jacks, and we use them daily,” says Robert Pier, CEO of DC Logistics. “Toyota outlasts the others and is the best product on the market today. They have better weight capacities and better turning ratios.”

Ruan agrees. “Not only is Toyota’s pricing competitive, but their world-class manufacturing and the quality of their equipment is second to none,” adds Frederiksen. “It is a great fit for us.”