Forklift Inspections & Pre-Operation Checklist

Forklifts are a common sight in many industries. Whether used in warehouses, manufacturing plants, retail applications, or elsewhere, forklifts are crucial tools in the daily operations and supply chains of most businesses. Because of this frequent level of use, many operators and nearby pedestrians can become complacent regarding safety protocols. This complacency can have many ill effects, including asset damage, employee discipline, fines, injury, and even death.

According to the Operational Safety and Health Administration (OSHA), an average of 100 employees are killed each year in forklift accidents, and as many as 95,000 total forklift accidents occur on an annual basis. In many cases, these accidents are avoidable. While Toyota forklifts are carefully manufactured with safety top-of-mind, safety protocols must be followed correctly for operators and pedestrians to be protected.

The Importance of a Forklift Inspection

Beyond behavioral causation, injuries and fatalities also stem from detectable equipment failure when employees do not properly inspect and assess equipment before use. Safety regulators, forklift manufacturers, and many companies encourage that forklifts be inspected before operating, but these inspections are often neglected or poorly documented. Safety is an obvious reason that these inspections should be conducted regularly, and so is compliance—thousands of dollars in fines could be levied based on failure to determine forklift safety prior to operation.

Protecting company reputation, finances, property, and lives against this sort of failure and related accidents typically requires only one measure be taken—pre-operation forklift inspections carried out according to a thorough checklist. In addition to the safety and compliance related aspects of regular forklift inspections, there is also a cost-savings component related to the proactive discovery of issues and predictive maintenance. Discovering problems, or festering problems, sooner helps limit and plan downtime and can be an easier, less expensive repair than a full-blown issue. Creating and adhering to a pre-operation inspection regiment is not inherently difficult, but it does take continuous corporate support and a high level of operator discipline.

Forklift Inspection: What Must You Do?

In its 29 CFR 1910.178 standard language, OSHA states that forklifts must be inspected either daily, or after each shift in cases where vehicles are in round-the-clock use. If problems are discovered, they must be reported and the forklift must be removed from service immediately. While there are no mandates in the standard as to precisely how the inspections must be conducted, there are suggested best practices readily available.

What Should Go Into a Toyota Forklift Daily Checklist?

If you do not have a pre-operational checklist for your forklifts established, do not worry—they are fairly intuitive. Manufacturers often provide sample checklists that are updated and customized as necessary. Referencing these directions are your best bet. If you wish to create your own checklist, though, the following are examples of checkpoints that should always be included in your daily forklift inspection:

- Check fluid levels (oil, water, and hydraulic fluid, for example)

- Check for leaks, cracks and visible defects everywhere on the forklift

- Check mast chains visually; avoid the use of hands

- Test mast chain tension by lifting the load backrest to eye level—the mast chains should be level and any tilting may signify stretching or broken rollers

- Check tire condition, pressure, and look for any cuts or gouges

- Determine fork condition, remembering to check the top clip retaining pin and heel

- Ensure load backrest extension functions properly

- Check functionality of finger guards

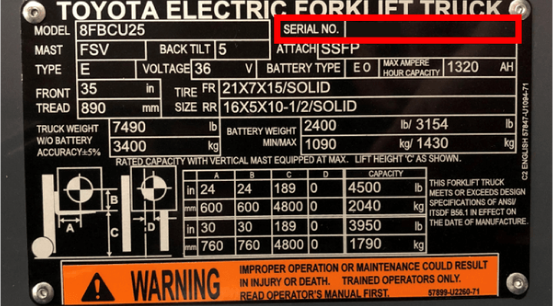

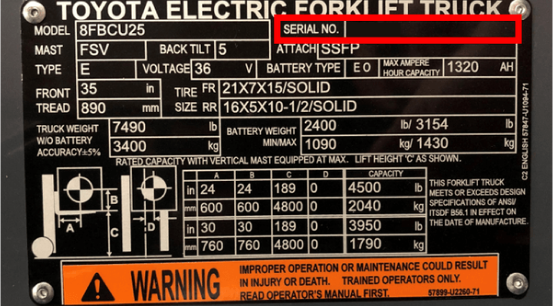

- Ensure safety decals and nameplates are legible and match the forklift model

- Check that the operators’ manual and log book are present and legible

- Ensure the operators’ manual compartment is clean of debris

- Test all functional safety devices, such as seat belts and horns

- Check the brakes, steering controls and other operational items for proper function

Depending on the type of forklift you are using, there may be other propulsion-specific aspects to check.

Electric Forklifts Pre-Operation Checklist

Here are a few items worth checking on your electric forklifts:

- There is no fraying or exposed wires in cables or connectors

- Battery restraints are functional

- Electrolyte levels are proper

- The hood latch is operational

Internal Combustion Cushion and Internal Combustion Pneumatic Forklifts Pre-Operation Checklist

Reach Trucks Pre-Operations Checklist And Order Pickers Pre-Operations Checklist

Here are a few items worth checking on your reach trucks and order pickers:

- On-truck and off-truck chargers are functioning

- No damage, bend, or looseness in the forks or backrest

- Brake pedal is effective

- No leaks can be detected

For more information about forklift inspection or to request a quote, please contact your locally authorized Toyota dealer.